Plant 1 – Retreading

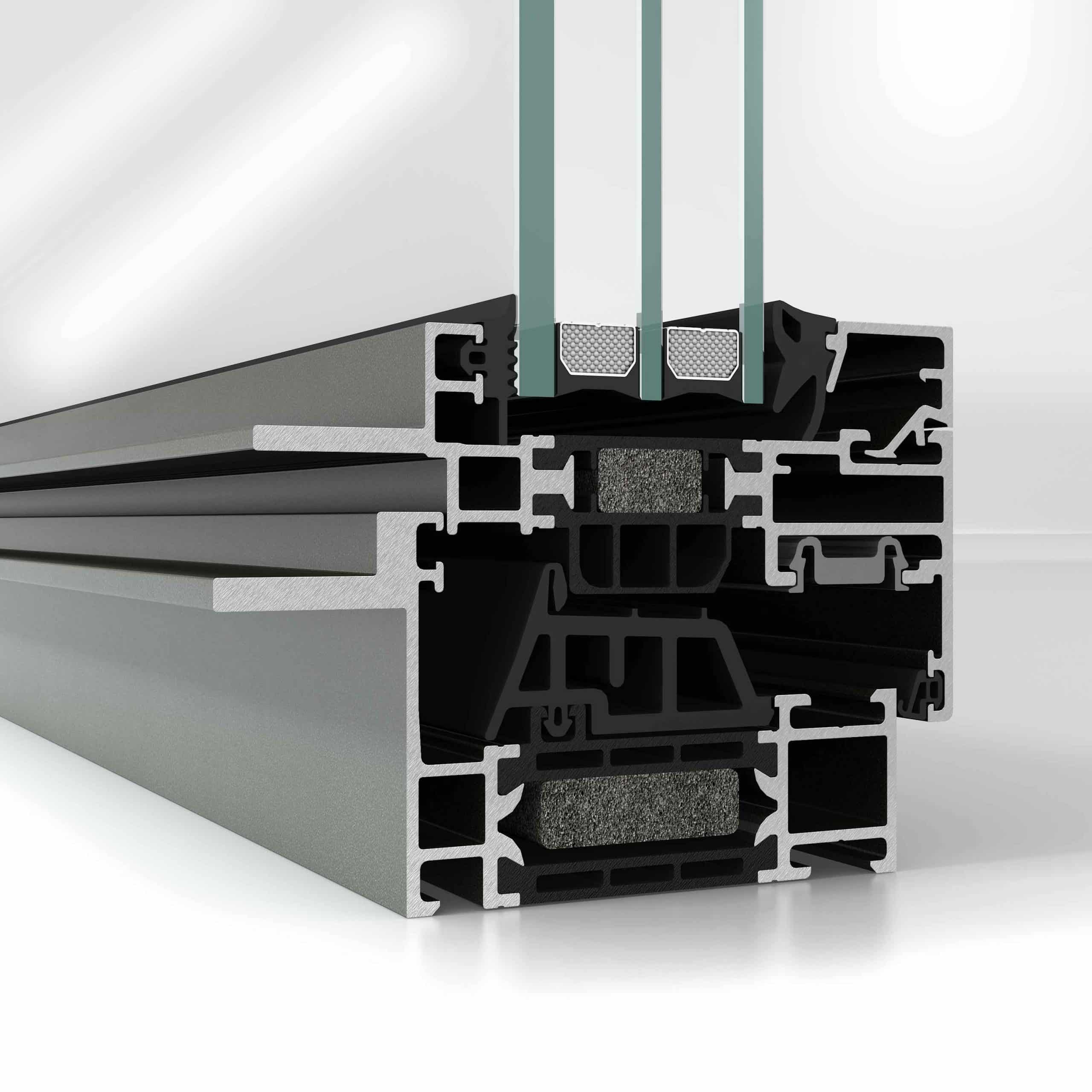

Plant 2 – Production of aluminum and steel windows

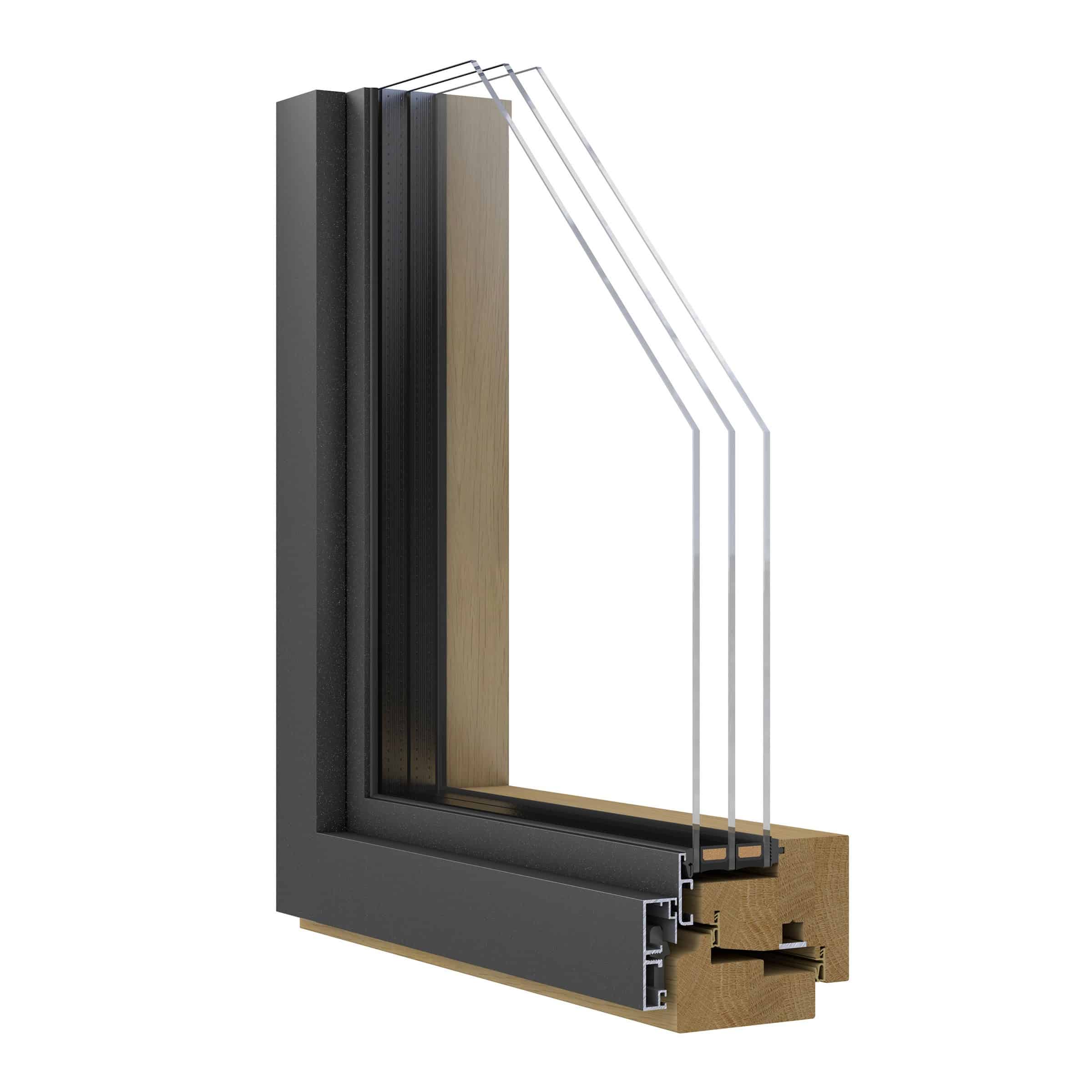

Plant 3 – Production of wooden windows and wood-aluminum windows

THE FAMILY BUSINESS TIMM FENSTERBAU – “MADE IN BERLIN”

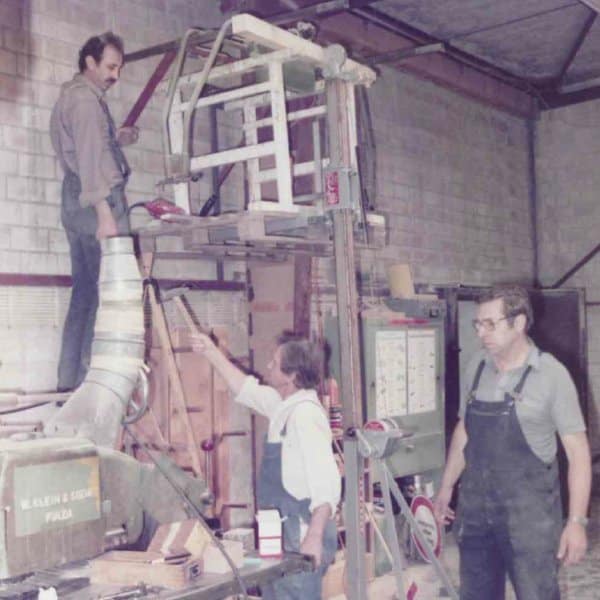

Hans Timm founded the company in 1957. After more than 60 years and already in its third generation, TIMM is now one of Berlin’s “long-established” family businesses, which has developed from a joinery into a medium-sized company with more than 150 employees.

Today, TIMM is one of the leading German window manufacturers, developing customized solution concepts for economical, energy-efficient and material-compatible window and façade constructions. The once traditional workbench has given way to ultra-modern, CNC-controlled machines that can manufacture any conceivable product with the utmost precision.

Hans Timm’s specialist knowledge, craftsmanship, but above all his curiosity, determination and commitment are the basis of the success story “TIMM Fensterbau – made in Berlin”, which now spans more than 60 years.

High-quality timber, timber-aluminum, aluminum, steel and security windows as well as exclusive façade elements are now manufactured at three locations in Berlin-Marienfelde on a production area of 14,400 m².

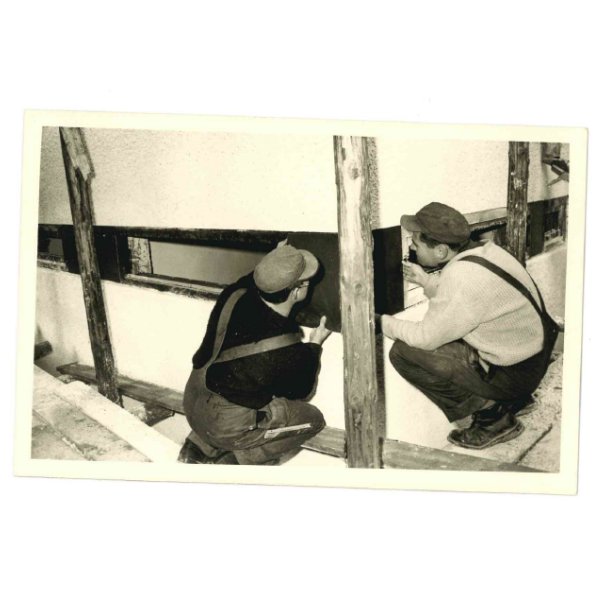

Hans Timm Fensterbau has always successfully met the constantly increasing demands in window and façade construction. In recent years, the refurbishment of historic window constructions has been added as a further business area – funded as a research project in cooperation with the Berlin Senate and the European Union.

In close cooperation with architects and clients TIMM develops individual special constructions that have led to our excellent reputation, even beyond Berlin’s city limits, but above all characterize the cityscape in Berlin.

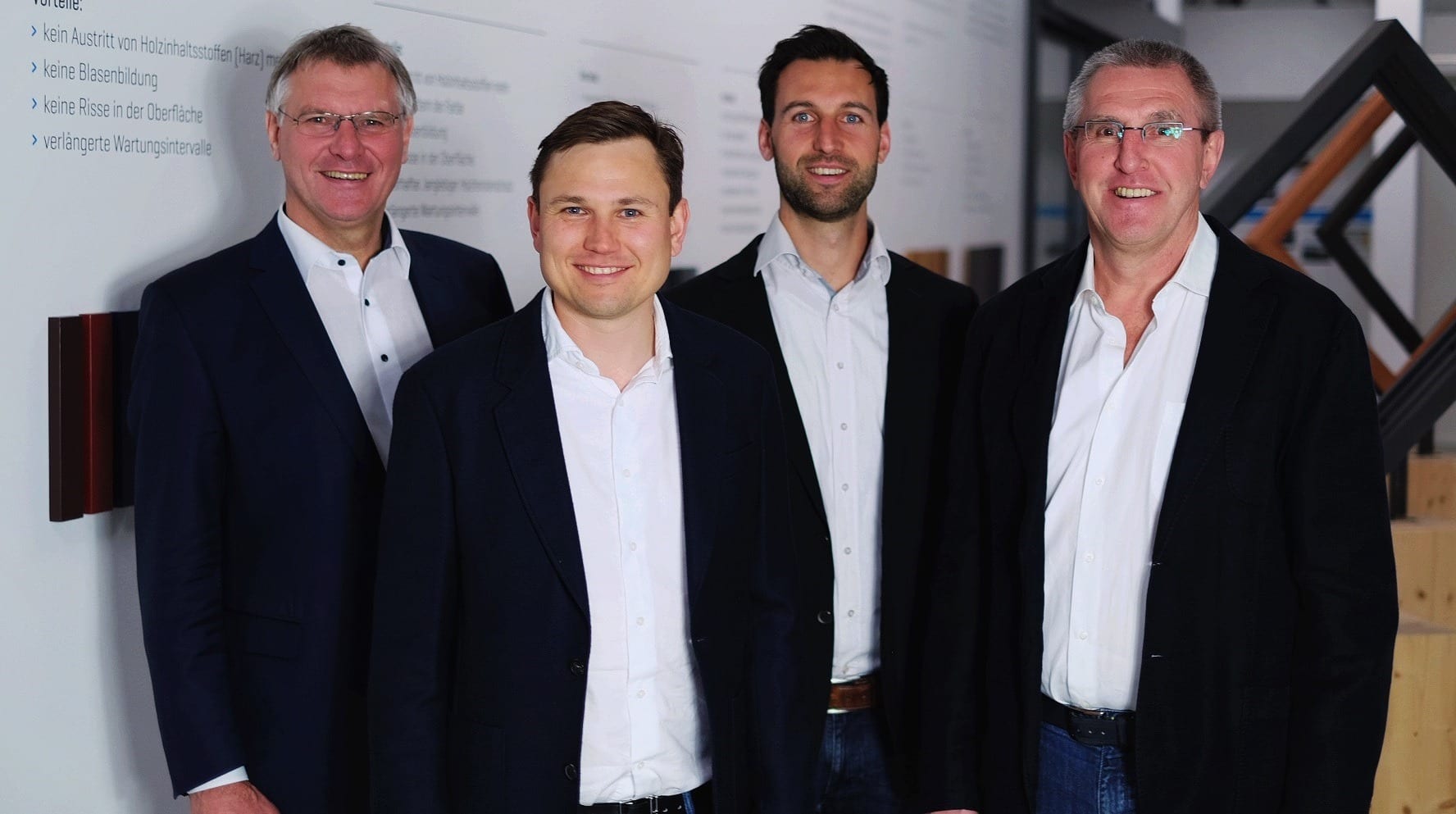

The two sons Detlef Timm and Bernd Timm and the grandsons Bastian Timm and Jonas Wilde have been successfully continuing the life’s work of the senior boss for years.

For three generations and more than 60 years, TIMM Fensterbau has stood for the highest quality and lasting values.

MANAGEMENT OF HANS TIMM FENSTERBAU

Detlef Timm

“We live 24 hours for windows.”

Bastian Timm

“As the third generation, looking back on over 60 years of company history, you feel a special responsibility. You want to maintain and preserve what is there. But the real task as a successor is to look ahead and think ahead.”

Jonas Wilde

“We want to use digitalization to complement the expertise of our employees to continuously improve quality from consultation to installation.”

Bernd Timm

“What our customers appreciate about us is that we are reliable and supply windows of the highest quality.”

THE SUCCESS STORY OF HANS TIMM FENSTERBAU

2024

Getting started with modular construction – TIMM module

With our new, innovative TIMM design window and façade module, Hans Timm Fensterbau is entering the modular window and façade construction market. The TIMM module perfectly integrates windows, sun protection, insect screens, fall protection, window sill/rigid gutter and ventilation in one module. It is available as a 2-stage installation (window + module) or completely as a 1-stage installation process (complete module).

2023

SCHÜCO AWS 75 Steel Look, designed by Timm

With its unique special profiles, the completely new aluminum construction for listed buildings enables the precise reproduction of historic steel windows in aluminum, and is extremely efficient to manufacture.

2023

Completion of the new wood-aluminum window system with low carbon

After more than 1.5 years of intensive development work, we are launching a completely new generation of wood-aluminum windows with a modular design. It sets new standards in energy efficiency, cost-effectiveness, sustainability and resilience to climate extremes. It is also the first window system in the world to be produced with low carbon aluminum materials and thus achieve a particularly lowCO2 footprint.

2022

Johanna Timm

After a successful degree in industrial engineering and ten years in management positions in the field of renewable energies, Johanna Timm joins our family business. She takes over the management of the service and retreading division and contributes her extensive expertise to all sustainability initiatives.

2021

Benedikt Swiatek

Benedikt Swiatek, Detlef Timm’s youngest son, joins the company as part of the 3rd generation after successfully completing a commercial apprenticeship and a degree in business administration in Cologne and Bonn.

2020

New paint system for plant 3

By investing in a robot-assisted painting system, Timm is underlining its innovative strength and sustainability. We completely rebuilt our paint system over Christmas 2020 with “open-heart surgery”. The new paint system represents the last major milestone in the 10-year modernization plan for our woodworking plant. The system features two state-of-the-art painting robots with 3D recognition, an automatic flooding system, halogen dryers and the latest conveyor technology. The new paint system will result in considerable savings in water, paint, CO2 emissions and grey energy for our customers and the new process quality will further improve our quality level.

2020

New TIMM design

The digital transformation and changing customer expectations have made it necessary to respond in terms of design.

2019-2020

Death of the founders

On 02.09.2019, our senior partner passed away at the age of 85, and just a few months later, on 12.03.2020, our company founder Hans Timm died at the age of 86. Our company is deeply connected to the history of the two founders, which began for us as an independent family business in 1957. From the very beginning, Timm has stood for uncompromising quality, for passion when it comes to elaborate details and special object solutions, and for values such as reliability, responsibility and cohesion. The 2. and The 3rd generation will preserve the legacy and think ahead.

2019

Security window

Through a comprehensive certification program, Timm is expanding its test certificates in the area of timber and timber-aluminium high-security windows and thus has a product range for the protection of buildings that is unique in Europe. With the same – very narrow – face widths, windows up to security class RC 4 can be manufactured without any aesthetic differences. With the extended certifications, there are no longer any restrictions on the design types for end users.

2018

Aluminum production

Due to the increasing demand for aluminium and steel products from our company, we are expanding and modernizing our production through several investments. We optimize all processes according to LEAN principles. At the heart of the new production facility is the CNC-controlled “Quadra L1” throughfeed center from Emmegi, which guarantees our customers cost-effective production and consistently high quality.

2018

The 3rd generation

Jonas Wilde, son of Detlef Timm, joins the company alongside his cousin Bastian after studying engineering (Bachelor) and logistics (Master) at the Technical University of Hamburg.

2017

Showroom opening

The conference and information center will provide the public with an exhibition space of over 800 m².

2017

Berlin Energy Saving Champion

Timm Fensterbau and its founder Hans Timm receive the “Berlin Energy Saving Champion” award from the Berlin Chamber of Crafts for their efforts to renovate historic box-type double windows.

2016

Detlef Timm is the new VFF President

Detlef Timm is elected successor to Bernhard Helbing by the VFF Executive Committee at the annual congress of the window associations in Palma de Mallorca on June 3, 2016.

2014

Berlin Monument Preservation Prize

On December 10, 2014, company founder Hans Timm received the Ferdinand von Quast Medal, the Berlin Monument Preservation Award, in recognition of his special services to the preservation of historical monuments.

2014

Investment program

Completion of the three-year investment program at Plant 3 incl. the complete renewal of the machinery and the revision of all window systems.

2013

Green Buddy Award

At a ceremony on the EUREF campus, Timm Fensterbau receives the Green Buddy Award in the area of production-related services / production for our initiation, development and long-term implementation of techniques for the refurbishment of wooden box-type windows.

2013

Handover of the management

On the occasion of Hans Timm’s 80th birthday, his sons Detlef and Bernd Timm take over the management of the company.

Securing property rights for the production of a closed parapet joint in timber frame constructions in window construction.

2010

Bastian Timm

Bastian Timm joins the company as the third generation after training as a banker and studying industrial engineering at the Technical University of Hamburg-Harburg.

2009

Federal Prize for Monument Preservation

For the second time, Timm Fensterbau receives the Federal Award for Craftsmanship in the Preservation of Historical Monuments.

2004

Federal Medal of Merit

Hans Timm is awarded the Medal of Merit of the Order of Merit of the Federal Republic of Germany for his extraordinary commitment to the preservation of old building facades and monuments.

2000

Research assignment

Research contract from the Berlin Senate and the European Union on the subject of retreading box-type windows.

New construction plant 3

New construction of Plant 3 at Motzener Strasse 6b – wooden window production.

1991

Plant 2 and engineering office

Commissioning of Plant 2 at Motzener Strasse 10, where aluminum, plastic and steel windows are produced. Founding of own engineering office.

1987

Bernd Timm

Bernd Timm joins the family business after training as a carpenter and studying wood technology in Rosenheim.

1984

Detlef Timm

After completing a degree in industrial engineering at the TU Berlin, Detlef Timm joins the company as the second generation.

1980

Aluminum windows and facades

Timm Fensterbau begins with the production of aluminum windows and facades.

1975

Extension plant 1

Expansion and extension of the production facility at Säntisstrasse 139 – today our Plant 1.

1973

First “finished window” & first PVC window

The first “finished window” in wood, including glazing and final coating, is produced. The first PVC window leaves the factory.

New construction of plant 1 in Marienfelde

Construction of the first own production building in Berlin-Marienfelde, Säntisstraße 139, specializing in the production of wooden windows.

1962

Factory floor in Schöneberg

Expansion of the production area and relocation to the factory floor in Belziger Straße in Berlin-Schöneberg.

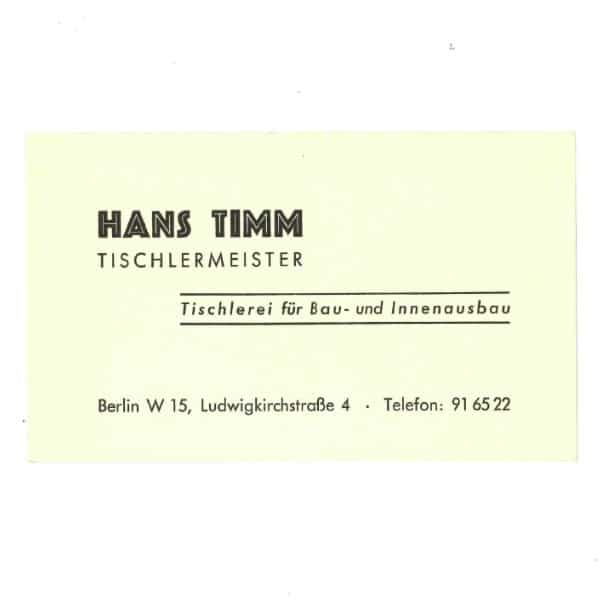

1957

Foundation at Ludwigkirchplatz

Founding of the “Hans Timm joinery for construction and interior fittings” as a store joinery on Ludwigkirchplatz in Berlin-Wilmersdorf.

SHOWROOM

Die innovativsten Lösungen der Branche

Auf rund 850 m² Ausstellungsfläche präsentieren wir Ihnen in unserem Showroom an über 60 Exponaten die aktuellsten und innovativsten Lösungen der Branche aus den Bereichen Aluminiumfenster, Holzfenster, Holz-Alu Fenster und Stahlfenster sowie Sicherheitsfenster und Fassaden.

Architekten, Bauherren und Partnern im Objektgeschäft bieten wir die Möglichkeit, alle Arten und Designsprachen von Fenstern und Fassaden zu erleben und sich von unserem vielseitigen Produktportfolio begeistern zu lassen. Wir laden Sie herzlich ein, diese Erlebniswelt für Ihre Bauvorhaben und Planungen zu nutzen.

Hinweis: Bitte besuchen Sie uns nach einem vorab mit uns vereinbarten Beratungstermin, da unser Showroom nicht auf Publikumsverkehr und spontane Besuche ausgerichtet ist.

WO SIE UNS FINDEN

TIMM KONTAKT

Hans Timm Fensterbau GmbH & Co. KGMotzener Str. 10

D-12277 Berlin

Beratungs- & Angebotsanfragen:

anfrage@timm-fensterbau.de

+49 30 720 831-70

service@timm-fensterbau.de

+49 30 720 831-60 Zentrale:

info@timm-fensterbau.de

+49 30 720 831-0